- Handy design with indirect lighting

- Flexible handling of section feeding

- Capable of using 3 weighing systems

- Optimal utilization of all facilities of the mill/mix plant

- Improved management and survey of production data

- Handles up to 50 raw materials, 50 recipes and control of stock

FlexMix is SKIOLD’s answer to the demands of modern farm feed production to control of production. It has been of great importance to construct a flexible and handy computer in order to make the daily operation easier. Extensions and new demands can easily be met, and a good survey of the production as well as easy access to necessary data for economical control.

FlexMix is adapted to modern production demands to flexibility - e.g. the system is controlled by raw materials, meaning that one raw material -e.g. wheat - can be stored in several different silos and not necessarily in the same. The system itself decides from which silo to take out the wheat, at the same time controlling consumption and stock automatically.

Another essential advantage is that the system can handle up to three different weighing systems thus permitting the proportion of very small quantities via a separate weighing system, e.g. liquid minerals.

FlexMix can control all mixing principles. Traditional principles with one mixer as well as the more sophisticated principles where the mixer has a pre and post bin with the production of several feed mixtures simultaneously.

FlexMix has as standard innumerable registrations and calculations offering the user a complete survey of financial and nutritional conditions of his feed production.

FlexMix automatically calculates 10 different production data, e.g. the price of the ready feed as well as content of energy, protein, amino acid, phosphorus etc.

All production data and alarms are registered for a possible later use. Apart from production data, the computer can register stock of raw materials and give alarm when the required minimum stock is reached.

FlexMix PC is the optimal tool for control of large and complex plants.

The system is based on a standard computer that via a connected PC with graphic software gives maximum view and is extremely handy.

The plant can be updated and operated via a modem which a. o. assures efficient service and correction of faults directly from the SKIOLD service department.

The mill is the largest consumer of energy in the plant, and so it is important to control the mill in the best possible way, because of energy consumption as well as achievement of optimal structure in the feed.

A combination of FlexMix with the SKIOLD disc mill offers an optimal utilization of its resources.

FlexMix can be programmed to vary the milling degree of the various raw materials in the various mixtures so that the correct structure for the various animal groups is obtained. This guarantees the best feed utilization and health.

With the SKIOLD FlexMix the modern farmer can meet with the future demands of increased flexibility and optimal control of his feed production.

FlexMix is equipped with a large illuminated display showing the user all necessary information in clear text. The operation is logic and possibilities of mistakes regarding operation are limited by a security incorporated in the programme. Each system is tailormade to the immediate needs, and the control panel of the computer is equipped with an individual flow diagram showing all machines in the plant. The flow diagram has built-in control lamps and push buttons for manual operation of the plant.

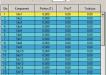

| Raw materials: 50 | Controls three stage mixing procedure |

| Recipes: 50 | Automatic regulation of milling degree |

| Up to 20 raw materials in each recipe | Alphanumeric display |

| No. of feed drops: 40 | Start of 24-hours clock |

| Handles 3 weighing systems | Start of sensor in silo |

| Macro and micro proportioning | Manual start via keyboard |

| Feed analysis for 10 component data | Connection of printer |

| Silo control with minimum stock | Connection of PC |

| Illuminated display | History of alarms |

| Separate weighing amplifier with possibility of weight read-out | 5 planów żywienia do karmienia sekcjami |

| Exact weighing in of small quantities | Five feed programmes for section feeding |

| PC control via graphic software |