- All-round use for powder and granulated material

- Agitator option for especially difficult material

- Painted or stainless construction

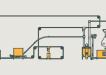

- Multiple combination options with transport equipment

- Safety grate

- Suspension for big-bags

- SKIOLD hoppers are often used in combinations with SKIOLD flex augers for transport and dosing of minerals

- Volume is increased by mounting of superstructure

- Various equipment for big-bag handling can be supplied

- Stainless and reinforcerced models are available

This is normally used for premixed mixtures to be conveyed to the mixer or wet feeding tank. At the conveying point of these mixtures, a flexible auger with a 40 mm pitch is used in order to obtain a low capacity and thus better accuracy at the weighing point into the mixer. Where there is limited space available, the two hoppers can be placed on top of one another, but please note that there is an increased filling height on the upper hopper.

Difficult Raw Materials

Certain raw materials do not flow easily in the hopper, i.e. fishmeal. In order to overcome this problem you can install an agitator (extra outfit) driven by a 0.37 kW gear motor. This makes the material flow constantly during emptying, thus preventing accumulation.

| Volume (liter) | Material | Agitator (kW) | Extension volume (m3) |

|---|---|---|---|

| 400/700 | Painted/stainless | 0,37 | 0,5/0,75 |

400 and 700 liters available for:

- Ø75 mm flexible auger

- Ø90 mm flexible auger

- Ø102 mm tubular auger